02

Aug

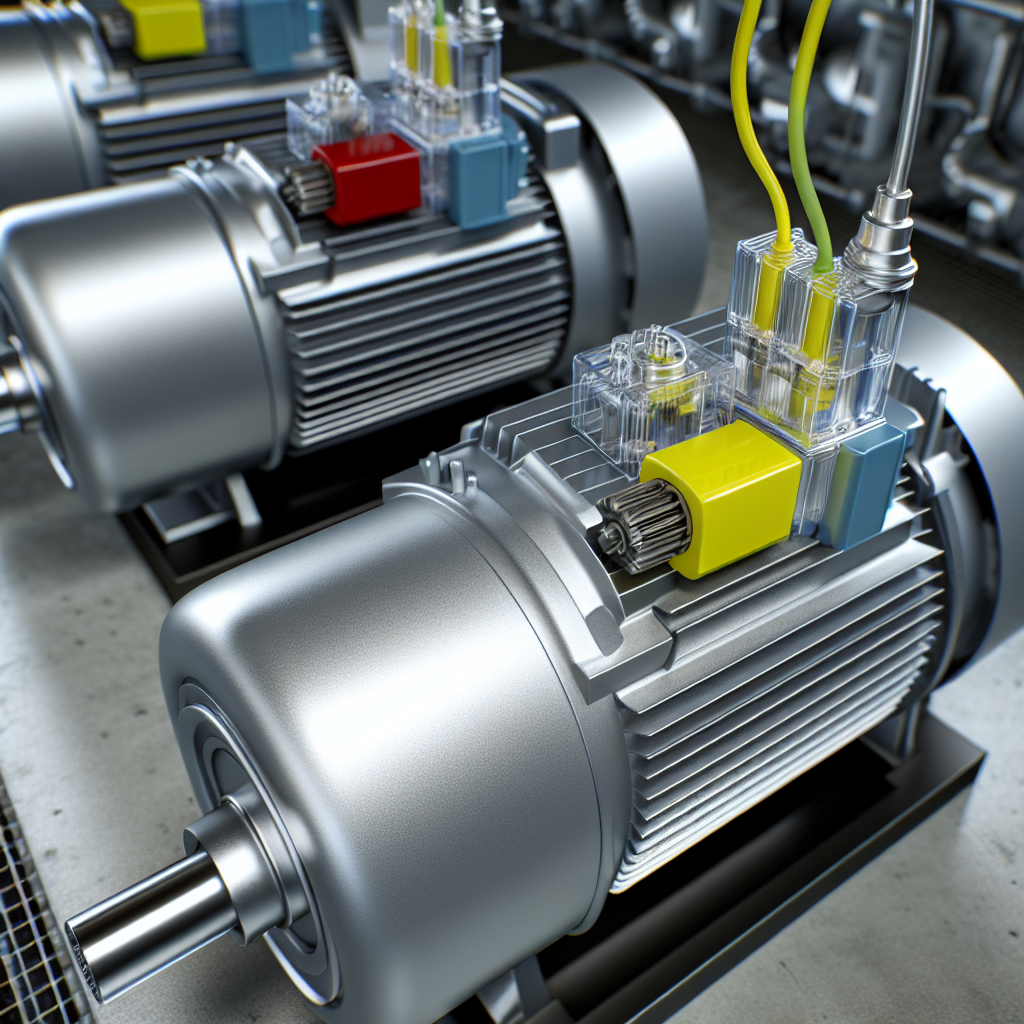

Modern industry relies on precise, reliable power conversion to keep production efficient and downtime low. High‑performance electric motors convert electrical energy into motion with minimal losses, supporting everything from conveyors and pumps to fans and compressors.

Performance, integration and lifecycle value

Selecting the right drive solution involves more than nameplate power: torque profile, duty cycle, enclosure rating, efficiency class, and control strategy all influence total cost of ownership. With robust bearings, optimized cooling paths, and compliant insulation systems, a high‑quality electric motor can deliver consistent performance across harsh environments while reducing maintenance intervals.

For engineers and buyers, seamless integration is equally important—matching shaft dimensions, mounting standards (B3, B5, B35), and voltage/frequency requirements speeds commissioning and minimizes retrofit work. Partnering with a supplier that provides complete documentation, testing data, and responsive support shortens project timelines. Explore specifications, configuration options, and service offerings on our site to streamline your next installation.

August 2, 2025