07

Aug

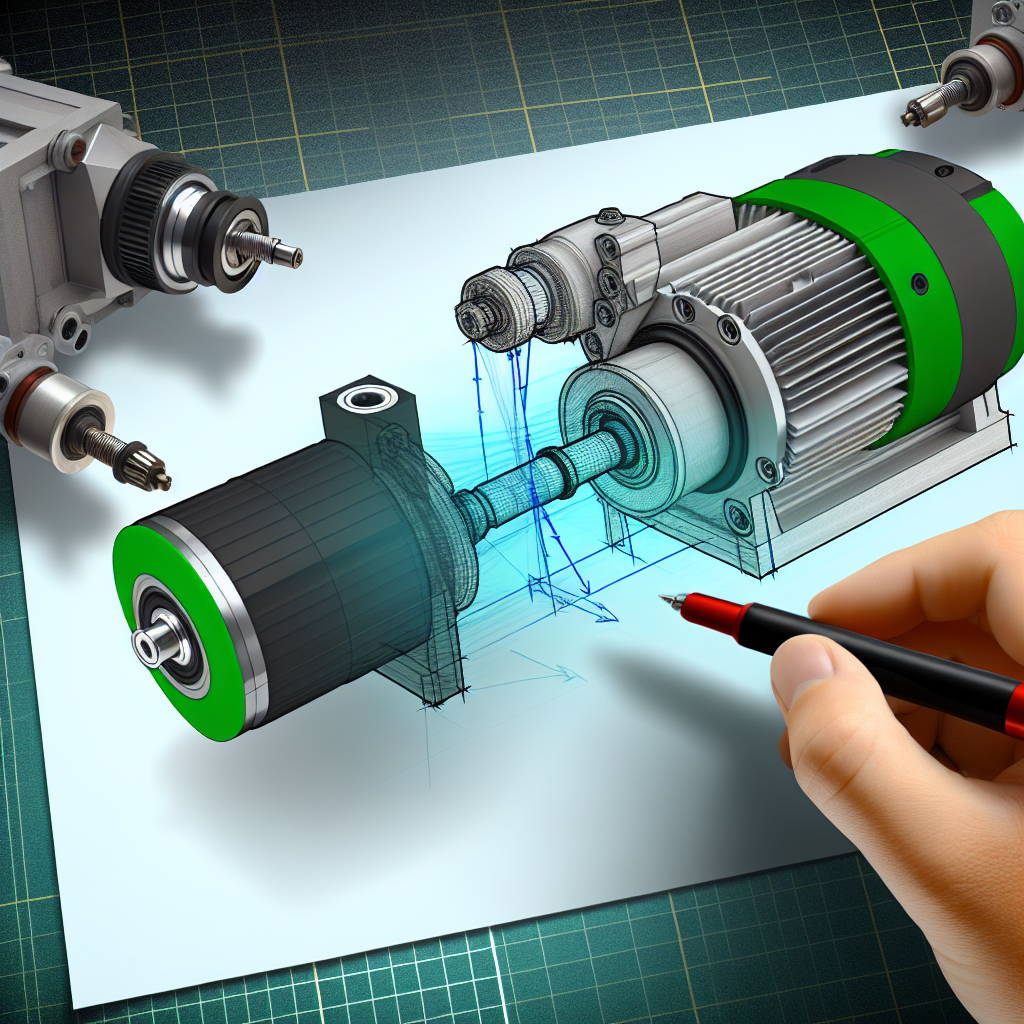

Reliable drive solutions are central to productive operations across manufacturing, HVAC, water treatment and logistics. By converting electrical energy into mechanical power with precision control, modern drives reduce downtime and energy use while stabilising processes. Explore availability, sizes, mounting options and documentation for electric motors that match your application and environment.

Specification, integration and commissioning

When selecting a drive, consider efficiency class (IE), duty type (S1–S9), required torque reserve, speed range, protection rating (IP), cooling method (e.g., IC411/IC416), bearing arrangement and environmental conditions. For variable‑speed operation, pair with an inverter‑ready design, proper EMC cabling and filters to minimise noise and bearing stress. Compare dimensions, flanges and performance data in the electric motors data sheets to ensure compatibility with existing equipment and controls.

Long service life depends on accurate alignment, clean power quality, correct lubrication intervals and condition monitoring (vibration and temperature). In harsh settings—dust, moisture or chemicals—specify enhanced sealing, coatings and appropriate ingress protection. For application support, lead times and the full catalogue, visit the UK portal and request a configuration tailored to your process.

August 7, 2025